The world of textile decoration is constantly evolving, with brands and creators always seeking new ways to make their garments stand out. While screen printing and standard heat transfer vinyl (HTV) have long been staples, foil direct plotter films are emerging as a game-changing technology. This method, which involves cutting a design from a specialized foil sheet and heat-pressing it onto fabric, offers a unique combination of visual brilliance and practical resilience that is perfectly suited for the demands of modern apparel.

Unmatched Aesthetic Appeal and Customization

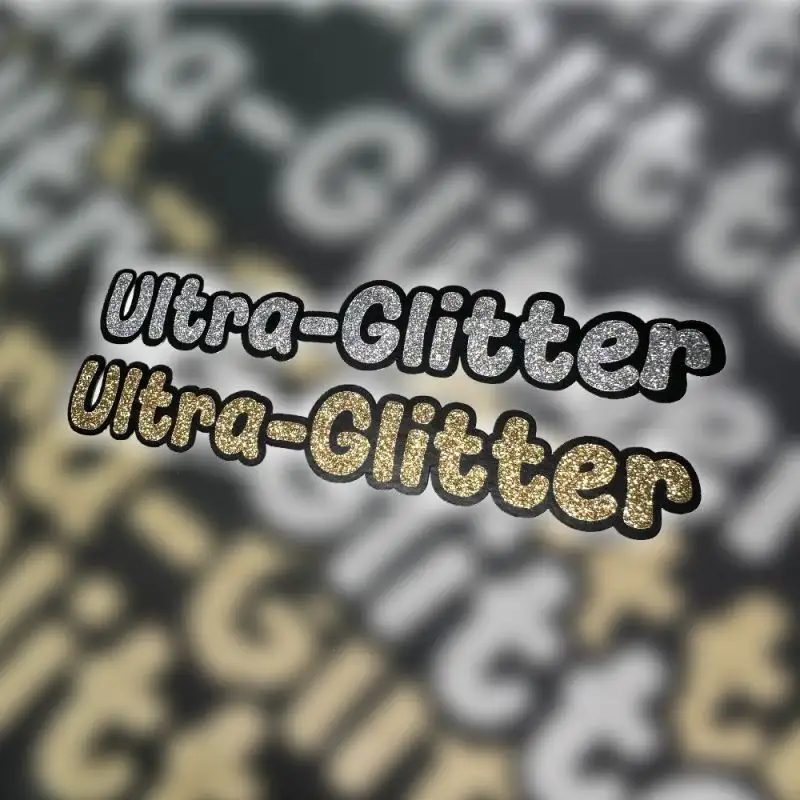

The most immediate advantage of using foil on textiles is the stunning visual impact it creates. Foil delivers a radiant, metallic shine that flat inks and standard vinyl simply cannot replicate. This luminosity catches the light and draws the eye, making designs pop with a premium, high-fashion quality. Furthermore, the range of available effects is vast. Beyond classic gold and silver, decorators can choose from holographic patterns, vibrant color pigments, marble effects, and even glow-in-the-dark finishes. This incredible versatility allows for limitless creativity, enabling the creation of everything from subtle, elegant logos for corporate wear to bold, attention-grabbing graphics for streetwear and performance apparel.

### Superior Durability and Wash Fastness

### Superior Durability and Wash Fastness

A common concern with any decorated garment is how well it will hold up after repeated washing. Foil direct plotter films, particularly those with a polyester base and cold-peel adhesive, excel in this area. Once properly applied, the foil becomes a durable, flexible layer that is highly resistant to cracking and peeling. The finish can withstand the rigors of commercial and home laundering, maintaining its integrity and shine far longer than many alternative methods. This durability is crucial for creating sportswear, work uniforms, or any apparel that needs to look professional and fresh through many cycles of use and cleaning, thereby protecting the brand’s image and ensuring customer satisfaction.

Enhanced Comfort and Breathability

For the wearer, comfort is paramount. Unlike some thick layers of plastisol ink used in screen printing, a properly applied foil finish is remarkably thin and flexible. It sits on the surface of the fabric without creating a heavy, plastic-like feel. This lightweight quality allows the textile to retain its natural drape, softness, and breathability. On activewear, this is a significant benefit, as it prevents the decoration from feeling restrictive or trapping heat and moisture against the skin. The result is a garment that is not only visually striking but also comfortable to wear for extended periods, enhancing the overall user experience.

Streamlined Production for Complex Designs

From a production standpoint, foil plotting offers distinct efficiencies, especially for intricate designs. The process of cutting the film with a plotter is ideal for handling fine details, small text, and complex logos that would be challenging and time-consuming to weed with traditional HTV. The clear carrier sheet on most foil films also allows for precise placement, ensuring every element of a detailed graphic is applied accurately. This capability to consistently produce sharp, clean, and sophisticated designs makes it an excellent choice for brands that rely on intricate branding or detailed artwork to define their identity.

A Tool for Brand Elevation and Value Addition

In a crowded market, perception is everything. Apparel decorated with foil instantly communicates a higher level of quality and value. A t-shirt with a foiled logo is often perceived as more premium and exclusive than one with a standard print, allowing brands to command a higher price point. This association with luxury makes foil an powerful tool for limited-edition releases, collaboration pieces, and high-end merchandise. By incorporating foil accents, brands can effectively elevate their product line, strengthen their market positioning, and create a more desirable and memorable product for their customers.

Embracing Eco-Conscious Decoration

As the textile industry moves toward more sustainable practices, foil plotting presents some environmental advantages over traditional methods. The process is dry, meaning it does not require the water usage associated with screen printing cleanup. Additionally, it generates no harmful VOC (Volatile Organic Compound) emissions like those from plastisol inks or some adhesive activators. While the film itself is a plastic-based product, the efficiency of the application process and the longevity of the final decorated garment—which doesn’t need replacing as quickly due to fading or cracking—contribute to a more sustainable product lifecycle.

A Lasting Impression on Fabric and Fashion

The integration of foil direct plotterfolien ↗ into textile decoration represents a significant step forward, blending art with advanced material science. It provides a solution that satisfies the creator’s desire for stunning aesthetics, the producer’s need for efficient application, the wearer’s demand for comfort and durability, and the market’s shift towards greater value and sustainability. By choosing this method, decorators and brands are not just applying a finish; they are investing in a technology that enhances the very nature of the garment, ensuring it makes a brilliant and lasting impression.