The production of high-strength cold rolled steel represents one of the most technologically advanced processes in modern metallurgy, requiring precise control over both mechanical and thermal treatments to achieve exceptional strength-to-weight ratios. HiTo Engineering has developed a sophisticated manufacturing approach that transforms conventional steel into high-performance materials capable of meeting the rigorous demands of automotive, construction, and aerospace applications. Their comprehensive process integrates specialized equipment with proprietary techniques to manipulate the steel's microstructure, resulting in products that offer superior strength, enhanced formability, and consistent quality. This meticulous approach to high-strength steel production has positioned HiTo as a trusted partner for industries where material performance is critical to product success and safety.

Specialized Material Selection and Preparation

The journey to high-strength cold rolled steel begins long before the rolling process itself, with careful selection and preparation of raw materials. HiTo Engineering starts with specific steel grades that possess inherent qualities suitable for strength enhancement, often utilizing micro-alloyed steels containing precise amounts of elements like niobium, vanadium, or titanium. These alloying elements interact with the steel's carbon content to create fine precipitates that significantly enhance strength during subsequent processing. The incoming hot-rolled coils undergo thorough inspection and surface preparation to ensure optimal conditions for the cold reduction process. This preliminary phase is crucial because even minor imperfections in the starting material can propagate through the entire process, compromising the final product's structural integrity and performance characteristics.

## Precision Cold Reduction and Work Hardening

## Precision Cold Reduction and Work Hardening

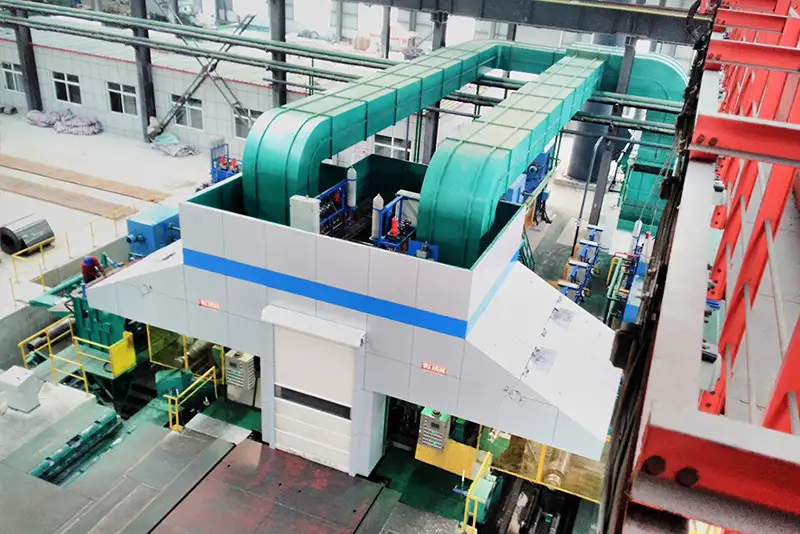

The core of HiTo's strength enhancement process lies in the precise application of cold rolling mill ↗ reduction, where the steel undergoes controlled plastic deformation at room temperature. Their specially designed rolling mills apply tremendous pressure, typically reducing material thickness by 50-90% in a series of passes. This severe mechanical working causes dislocation movements within the steel's crystalline structure, creating an increasingly dense network of entangled dislocations that resist further deformation. The result is significant work hardening, where the steel's yield and tensile strength increase dramatically while its elongation capacity decreases. HiTo's advanced mill controls ensure uniform reduction across the entire strip, preventing inconsistent mechanical properties that could compromise the material's performance in critical applications.

Controlled Annealing for Microstructural Optimization

Following the intense cold working, the steel possesses high strength but limited ductility, making it unsuitable for most applications. HiTo Engineering addresses this through precisely controlled annealing processes that carefully manipulate the steel's microstructure. Their continuous annealing lines heat the cold-worked steel to specific temperatures where recrystallization occurs, transforming the distorted grain structure into new, strain-free grains. The exact time-temperature parameters are critically important, as they determine the final grain size and thus the balance between strength and formability. For high-strength grades, HiTo employs special annealing cycles that may include rapid heating, precise soaking, and controlled cooling rates to develop optimal microstructural characteristics that provide the desired mechanical properties.

Advanced Tempering and Strength Enhancement

After annealing, HiTo Engineering often applies additional thermal treatments to further enhance the steel's strength characteristics through precipitation hardening and microstructural refinement. Their tempering processes carefully control the formation and distribution of fine carbides and other precipitates within the steel matrix, which create additional barriers to dislocation movement and thereby increase strength. For certain high-strength grades, they may employ accelerated cooling systems that create specific phase transformations, developing complex microstructures containing bainite or martensite phases that offer exceptional strength properties. These advanced thermal treatments require extremely precise control over temperature uniformity and cooling rates, achieved through HiTo's innovative furnace designs and quenching technologies that ensure consistent results across the entire coil.

Sophisticated Surface Treatment and finishing

The production of high-strength cold rolled steel isn't solely about mechanical properties—surface characteristics are equally important for many applications. HiTo Engineering incorporates advanced surface treatment processes that enhance both the appearance and performance of their high-strength steels. Their processing lines may include skin-pass rolling with textured rolls to improve surface finish and control yielding behavior, along with various coating or plating processes that add corrosion resistance or improve paint adhesion. For some applications, they apply specialized chemical treatments that create conversion coatings which further enhance the steel's durability and performance in demanding environments. These surface enhancements ensure that the high-strength steel not only performs well structurally but also meets the aesthetic and durability requirements of end-use applications.

## Rigorous Quality Assurance and Testing

## Rigorous Quality Assurance and Testing

Throughout the entire production process, HiTo Engineering maintains rigorous quality control measures to ensure that every coil of high-strength steel meets exacting specifications. Their quality assurance protocol includes non-destructive testing methods such as ultrasonic thickness monitoring, eddy current testing for surface defects, and laser-based shape measurement systems. Destructive testing of samples from each production lot provides verification of mechanical properties including yield strength, tensile strength, elongation, and hardness. Additionally, they conduct specialized tests for specific application requirements, such as hole expansion ratios for automotive components or fatigue testing for structural applications. This comprehensive approach to quality assurance ensures that HiTo's high-strength cold rolled steel delivers consistent, reliable performance in even the most demanding applications.

Customization for Specific Application Requirements

Recognizing that different applications require different combinations of properties, HiTo Engineering offers extensive customization capabilities within their high-strength steel production process. They can adjust numerous parameters throughout the production sequence to develop steels with specific property combinations tailored to particular applications. For automotive safety components, they might optimize for high energy absorption and specific deformation characteristics. For construction applications, they might focus on yield strength and weldability. For consumer products, they might prioritize surface quality and forming characteristics. This ability to fine-tune the production process allows HiTo to create application-optimized high-strength steels that provide exactly the right balance of properties for each specific use case, delivering superior performance and value to their customers.