Huachang Filter has earned a reputation as a premier automotive filter manufacturer through its meticulous and innovative manufacturing process. Behind this success lies a comprehensive approach that combines advanced technology, strict quality control, and a deep understanding of automotive needs. From raw material selection to final product testing, every step is designed to ensure that each filter meets the highest standards of performance, durability, and reliability. The company’s commitment to excellence is embedded in their manufacturing philosophy, which emphasizes precision and innovation at every stage. By maintaining a transparent yet rigorous behind-the-scenes process, Huachang has positioned itself as a leader capable of delivering products that safeguard engines and enhance vehicle performance across the globe.

Advanced Material Selection and Development

The foundation of Huachang’s superior auto filter manufacturers ↗ begins with the careful selection of raw materials. The company sources only high-quality filtering media, such as synthetic fibers and specially treated cellulose, which are known for their exceptional dirt-trapping capabilities and durability under extreme operating conditions. Their team continuously researches and tests new materials that can improve filtration efficiency while reducing resistance to oil flow, which is crucial for engine performance. Huachang also invests in developing proprietary media blends that enhance the lifespan and effectiveness of their filters. This focus on material science ensures that their products can withstand the pressures, temperatures, and contaminants typical in modern engines, providing reliable protection and long service life for vehicles.

Precision Engineering and Manufacturing Techniques

Precision Engineering and Manufacturing Techniques

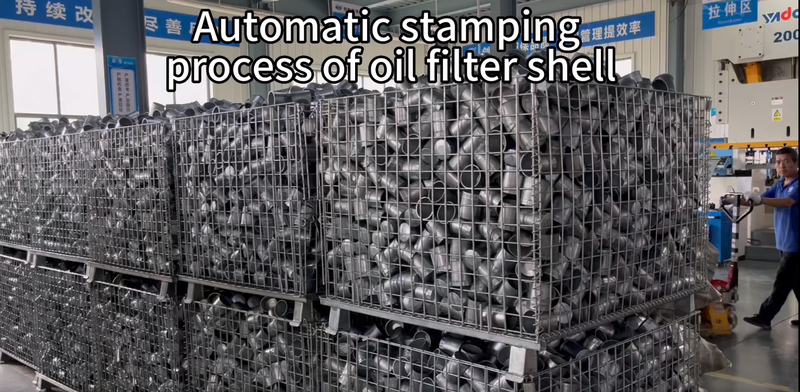

Once the raw materials are secured, Huachang’s manufacturing process shifts to precision engineering. Their factories are equipped with state-of-the-art machinery capable of producing filters with highly consistent dimensions and tight tolerances. The manufacturing process incorporates automated cutting, folding, and bonding techniques, which significantly reduce human error and ensure uniformity across large production batches. Special attention is paid to the sealing mechanisms and structural integrity of each filter, as these are critical to prevent leaks and maintain filtration efficiency. Huachang’s engineers work closely with designers to optimize filter shapes and sizes for compatibility with a wide range of vehicle models. This meticulous approach to manufacturing ensures that every filter performs precisely as intended, providing dependable engine protection.

Quality Control and Testing Procedures

Behind every Huachang filter is a comprehensive system of quality control and testing designed to catch any imperfections before the products reach customers. Their quality assurance process begins with raw material inspection and continues throughout the manufacturing cycle. Each batch of filters undergoes rigorous testing, including filtration efficiency assessments, pressure resistance tests, and durability evaluations under simulated engine conditions. The company employs advanced testing equipment capable of mimicking real-world operating environments, ensuring that filters can withstand the rigors of daily use. Regular audits and inspections are performed at every stage to verify compliance with international standards. This relentless focus on quality ensures that Huachang’s filters consistently deliver optimal performance, providing peace of mind for vehicle owners and manufacturers alike.

Innovative Design and Continuous Improvement

Innovation is at the heart of Huachang’s process, and their R&D team plays a vital role in continuously improving existing products and developing new solutions. Their engineers analyze feedback from the field, monitor industry trends, and incorporate the latest technological advancements into their designs. For example, they develop multi-layer media structures that improve dirt-holding capacity without increasing resistance, and they innovate sealing technologies to prevent leaks even under high-pressure conditions. Huachang also explores eco-friendly manufacturing practices and materials that contribute to sustainability goals. This culture of continuous improvement ensures that their filters stay ahead of the curve, capable of meeting the evolving demands of modern vehicles, including electric and hybrid models, which may have different filtration requirements.

Global Standards and Certification Processes

Global Standards and Certification Processes

Huachang’s behind-the-scenes process is also characterized by their rigorous adherence to international standards and certification protocols. They ensure that all their products comply with industry benchmarks such as ISO/TS 16949, which emphasizes quality management in automotive manufacturing. Their products are regularly tested to meet certification requirements for various markets, including North America, Europe, and Asia. This global focus on standards not only enhances the credibility of Huachang’s products but also facilitates their export and cooperation with international automotive brands. Certification processes involve detailed documentation, testing, and audits that validate the safety, quality, and environmental compliance of their filters. By aligning with these rigorous standards, Huachang demonstrates its commitment to providing trustworthy, high-performance products worldwide.

Sustainable Manufacturing and Environmental Responsibility

Sustainability is an integral part of Huachang’s behind-the-scenes operations. The company actively seeks to reduce its environmental footprint by integrating eco-friendly practices into every stage of production. This includes recycling waste materials, minimizing water and energy consumption, and developing longer-lasting filters that reduce waste generated from frequent replacements. Huachang also explores biodegradable materials and environmentally friendly manufacturing techniques that lessen their impact on ecosystems. Their commitment to sustainability not only aligns with global environmental goals but also ensures that their products contribute to cleaner emissions and greener driving experiences. By prioritizing eco-conscious practices, Huachang demonstrates that quality and environmental responsibility can go hand in hand, making them a truly forward-looking leader in the automotive filter industry.

In conclusion, Huachang’s behind-the-scenes process as a premier auto filter manufacturer reflects a harmonious blend of advanced materials, precise engineering, rigorous quality control, innovative design, strict adherence to international standards, and environmental responsibility. Each step in their production cycle underscores their dedication to delivering high-quality, reliable, and sustainable products that protect engines and meet the needs of modern vehicles. Their comprehensive approach to manufacturing not only ensures superior performance but also reinforces their reputation as a trusted leader in the automotive filtration industry, committed to excellence at every level.